DRUM SCREENS

WATER FLOWS FROM INSIDE TO OUTSIDE

PURPOSE AND APPLICATION

Drum screens are used to arrest the small debris contained in a large flow of water so that the downstream users remain unobstructed and clean (condensers, exchangers, spray nozzles, membranes, etc.). The debris can be of all types including fish, shrimps, jellyfish, leaves, grass, man-made refuse, plastics, seaweed, etc.

Drum screens are used in thermal and nuclear power plants, LNG terminals, desalination and fertilizer plants, drinking water and irrigation plants. They are especially recommended for very large flow rates.

DESCRIPTION

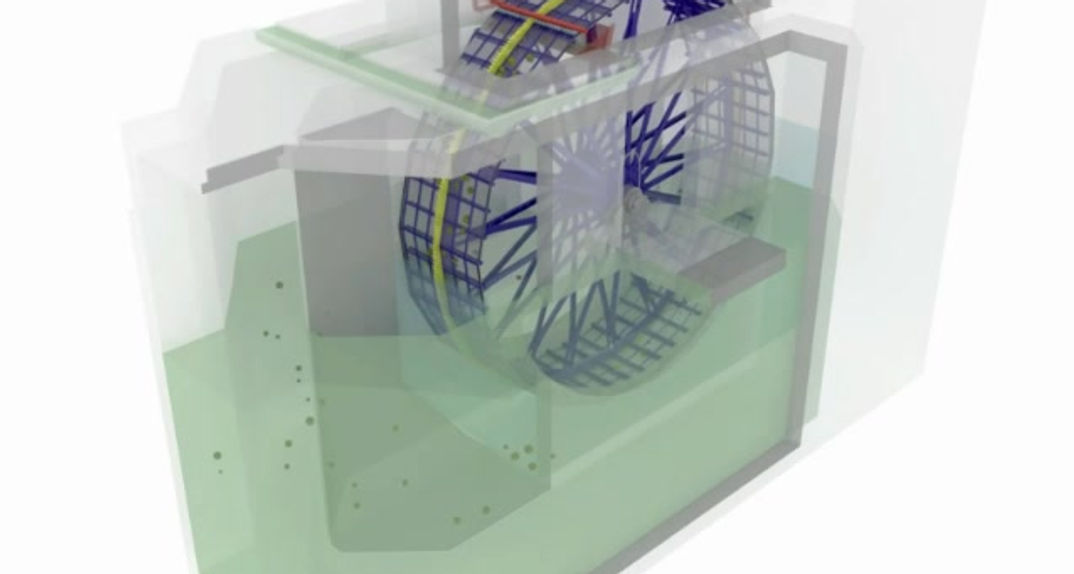

The drum screen is installed in a concrete chamber between two parallel side walls with large apertures. The drum consists of a cylindrical rotor with a cylindrical surface made of side-by-side rectangular mesh panels. The rotor has two bearings and a drive at deck level. The panels travel down into the water. The water flows into the inside of the drum screen via the two side-wall apertures and flows out after passing through the mesh via the screen chamber’s back outlet.

The debris-laden panels travel up to the deck level. One or two spray pipes with fantail jet nozzles set on the downstream side of the panels within the screen’s head structure, back-wash the panels and remove the debris which are projected into an internal collection trough. They travel in a deck flume to the debris disposal system (basket, separator, etc.).

The screens are normally stopped and are washed periodically when obstructed by the debris. Permanent rotation can be provided.

ADVANTAGES

90 years’ experience

Permanently resists high levels of head-loss

Large debris-handling capacity

Well-suited for permanent rotation

Compact civil structure

Fully-automatic

Fish-friendly option

Next to no maintenance required.

Cost effective

NECESSARY ANCILLARIES

Spray-water supply circuit

Head-loss monitoring system

Electrical control cabinet

Upstream bar rack (25 to 75 mm spacing (1 to 3”))

Pit dewatering stoplogs

Trash collection system (basket, etc.)

SIZES AND DATA

-

Mesh aperture from 1x1 to 10x10 mm (0.04 to 3/8”), or less upon special request

-

Flow rate up to 120000 m3/h (300000 gpm)

-

Tidal variation: no practical limit

-

Panel frame useful width: 1.3 to 6 m (2 to 13 ft)

Wider machines on special request (two-wheel layout)

OPTIONAL FEATURES

Two or three-speed operation

Seismic qualification

Special high travel speed design for handling very heavy debris loads

Jellyfish lifting trays

Screening medium resistant to fiber build-up

Screening medium preventing jellyfish adherence

Low pressure water-life protection system

“Scoop-a-fishTM” total fish survival system

Atex compliance

By-pass valves

MATERIALS

-

Drum rotor, mesh carrying structure, hub and shaft, bearing blocks:

For fresh-water applications: painted carbon steel or AISI 304L stainless steel

For seawater applications: AISI 316L stainless steel with anodes

-

Transmission shaft and bearings:

For fresh-water applications: carbon steel or AISI 304L stainless steel

For seawater applications: AISI 316L stainless steel, duplex or super-duplex stainless steel

-

Bolts, nuts, washers:

For fresh-water applications: A2 or A4 stainless steel

For seawater applications: A4, duplex or super-duplex stainless steel

-

Small fittings, spray-water pipes:

For fresh-water applications: AISI 304L stainless steel

For seawater applications: AISI 316L, duplex or super-duplex stainless steel

-

Screening mesh frames:

For fresh-water applications: AISI 304L stainless steel or composite

For seawater applications: AISI 316L, duplex or super-duplex stainless steel or composite

-

Spur gear and pinion:

Composite materials, carbon steel or cast iron (stainless steel in special cases)

-

Seals:

Composite materials or rubber

-

Debris-collection trough:

GRP, AISI 316L, duplex or super-duplex stainless steel

-

Anodes:

None required for fresh-water applications

For seawater applications: anodes are required for use with AISI 316L stainless steel and sometimes for duplex stainless steel