MICROFILTRATION

MICROSTRAINING, sometimes also referred to as MICROFILTRATION, MICROSCREENING or MICROSEIVING, is a water-screening process that uses very fine mesh fabrics to arrest all particles larger than the mesh aperture and a large proportion of the particles smaller than the mesh aperture.

BEAUDREY pioneered in this field with research starting in 1938 and the first industrial plants in 1950. Since then, the microstrainers have evolved with experience feed-back. BEAUDREY is the company with the largest and most exhaustive experience in this field.

FIELD OF APPLICATION

Microstraining is used in the following applications:

-

As the preliminary treatment of drinking water drawn from lakes, reservoirs and rivers.

-

As complete treatment of water for industrial purposes.

-

As tertiary treatment for sewage water.

-

As a means of recovering valuable fine particles or plankton from effluent waters.

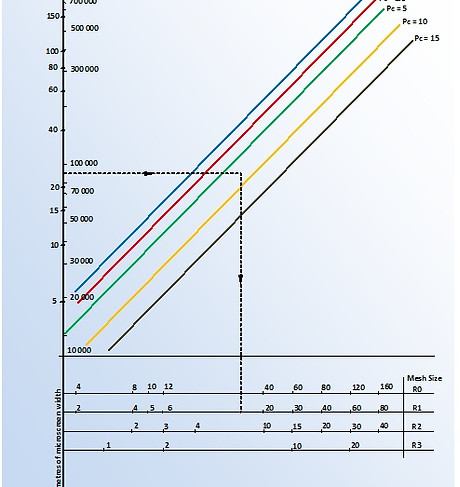

MEASUREMENT OF THE QUALITY OF WATER

The efficiency and capacity of a microstrainer in a water intake, depend upon several factors including the quality of the water to be purified, the characteristics of the fine straining fabric, the rotation speed of the microstrainer and the quantity of backwashing water. BEAUDREY developed a method of measurement of the quality of water which consists in measuring the flow of water across a given area of fine mesh of the type used in an industrial microstrainer. The BEAUDREY method ("Pouvoir Colmatant Beaudrey" consists in a constant head and decreasing flow system.

The BEAUDREY Colmatometer is used to measure the water quality, generally in laboratory conditions but can also be adapted for on-field testing.

This method of measurement is the subject of AFNOR standard T900300.

POUVOIR COLMATANT / CLOGGING CAPACITY